Now the assembly-building so popular, you know the three types of prefabricated housing development model?

What is a prefabricated house?

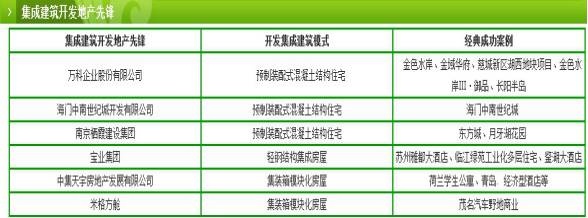

Prefabricated houses, ie houses, are constructed by industrialized production methods. They are houses that are constructed by partially or completely prefabricating parts of the house in the factory and then transported to the construction site and assembled by means of reliable connections. Europe and the United States and Japan are called industrialized or industrialized residential housing. Prefabricated housing is divided into three major development model: prefabricated reinforced concrete structure, prefabricated lightweight steel structure, prefabricated container houses.

Prefabricated housing system

.jpg)

Development mode 1: prefabricated concrete structure houses

.jpg)

Vanke advance "prefabricated concrete structure" housing industry

Vanke is the forerunner of the domestic housing industry, early in the cognitive stage, Vanke after a variety of international industrial housing system research, combined with the actual situation in China, and ultimately from the light steel structure, wood structure, precast concrete structure three kinds of residential The choice of prefabricated concrete structure residential Vanke factory as the direction of development. At the same time, through the study of the precast concrete structures in Europe, Hong Kong and Japan, it is found that Japan's prefabricated concrete structure residential technology is the most suitable for our country. More

What is the prefabricated concrete structure (PC)

PC (Prefabricated Concrete Structure) "prefabricated concrete structure", is a precast concrete member as the main component, by the assembly, connection, part of the cast with the formation of the concrete structure. The PC component is a finished concrete component formed by factory production of component processing units. First proposed the PC housing industrialization behavior is represented by the United States and Europe and the United States, after World War II, the first to propose and implement the PC housing industry of the road. PC housing with high efficiency and energy saving, environmental protection, reduce costs, providing residential functions and performance, and many other advantages. In today's international construction field PC project use form, countries and regions are different in mainland China is still the development and research phase.

Development of prefabricated concrete houses of the 10 major advantages

1, it is conducive to improving the quality of the external walls often cure leakage, cracks common problem.

PC floor of the external wall PC board is prefabricated in the factory, the door window frame is poured in PC board before the concrete is installed in the steel mold, so pouring concrete when the box and the concrete can be very good mesh together to avoid the easy water seepage Of the gap, the probability of water seepage is only one ten thousandth.

2, is conducive to speed up the progress of the project.

PC board outside the wall tiles, window frames, etc. have been done in the factory, the scene does not require external scaffolding. Local glue, paint, only the basket can be carried, do not take up the total duration. On the 10-18 floor of the floor, this alone can save the duration of about 3-4 months.

3, is conducive to promoting resource integration, improve management efficiency.

In the future full implementation of industrialization, build a house, sell a house, as to IKEA procurement, components are standard, the structure can be combined, the assembly can be simple to complete. As the PC to a certain extent, has finished the product assembly, combination, management is also easy, the effect is great.

4, is conducive to capital operation.

The real estate industry is capital - intensive enterprises, capital turnover rate, recovery speed is very important. The PC building as a result of construction speed, completion of early, early return of funds can be.

5, is conducive to improving the quality of building products, to win customers.

After the PC floor, because the tiles in the factory and the concrete firmly bonded together to prevent the "freeze-thaw" phenomenon, the basic put an end to the tiles off, PC products can not endure forever, "youth."

6, is conducive to reducing the intensity of the work of the owners of management.

Due to the prefabrication of the products in the factory, the monitoring of quality control points such as conventional on-site installation of doors and windows can be reduced, and the number of contracts is reduced and the management personnel are relatively easy. The number and quality of projects managed can be increased.

7, is conducive to the construction site of civilization construction, safety management.

Traditional work is a large number of workers in the construction site, high-altitude fall, electric shock, object strikes and other accidents are the highest frequency of the first three. The factory is a large number of site operations moved to the factory, on-site workers can reduce the maximum 89%, greatly reducing the incidence of on-site security incidents.

8, is conducive to environmental protection, conservation of resources.

Japan, the United States has reached more than 50% of construction PC. China's current GDP per 1 million US dollars of energy consumption for the 1274 tons of standard coal, 2.5 times higher than the United States, 8.7 times higher than Japan. After the construction of large-scale factory building, steel templates and other re-use rate increased, 83% reduction in waste, material loss by 60%, building energy efficiency more than 50%.

9, is conducive to creating an atmosphere of enterprise innovation, more innovative fruits.

Good and fast to sustainable development of enterprises, almost and innovation is solidarity, innovation is the soul of enterprise development. As the PC itself is an innovative project involving design, construction, materials, processing and so need to have a traditional approach is not the same innovative ideas, innovative management.

10, is conducive to business "high performance" model in depth.

If the PC is large, the design standardization, can greatly increase the number of cycles of the use of the steel formwork, thereby substantially reducing costs. Coupled with the total package, processing plants, materials, such as the formation of competition, new technology is likely to reduce the cost to 25%.

Development mode two: prefabricated steel structure housing

.jpg)

Steel structure residential prospects

Foreign advanced steel structure buildings have more than 50% in Japan up to 70%, while China is less than 10%, more than 90% is still RC building structure. In 2001, the Ministry of Construction issued the Technical Guideline for Steel Structure Industrialization. 10 years, the Ministry of Construction to promote the steel structure of residential research has been as many as 40 batches of pilot projects countless. China's steel structure housing must be vigorously developed, China's real estate developers should be able to see opportunities, the key is how to organize industrial production. Industrial production will promote China's economic development of new growth points. If the RC structure of the development of the construction from the manual into the mechanization, then the application of steel structure will make the modernization of residential construction.

About light steel houses

It is a green building system with high efficiency, energy saving, environmental protection and sustainable development policy. It is characterized by light weight, large span, good wind and seismic resistance, thermal insulation, sound insulation and other indexes. For villas, multi-storey residential, resorts, clubs and other civil buildings and building additional layer, the roof-to-slope, such as light within the wall. Pre-assembled, the wall includes pre-installed external wall envelope, insulation and windows. Roof truss systems can also be pre-assembled in the form of available to developers, compared with the traditional construction methods, greatly reducing the duration.

Development model 3: prefabricated container modular housing

.jpg)

.jpg)

Alternative "developer" of container housing construction

Low investment, a lot of money, is the container room "developers" were born of the two major causes, and high prices, security system for the indirect loss of money to fuel the road. "Developers" who want to grab a slice of the "housing market" for their huge amounts of money are now trying another "development" shortcut - a market for containerized housing. In the field of logistics used paint off, box deformation of the container, in the transformation into housing, one side is a low-cost capital investment, the other is the second use of waste wood waste of low-carbon move. So the channel through this way sideways into the housing market, why not?

What is a container house?

To the container as the basic module, the use of manufacturing mode, in the factory to complete the assembly line to build the structure of the module and internal decoration and then transported to the project site, according to different uses and functions quickly combined into different styles of housing construction.

.jpg)

.jpg)